Case 10 Mower Manual

Buy J I Case T10 Mower Trail Type Operators Instruction Manual Bar Mower Cutter Path: Spare & Replacement Parts - Amazon.com ✓ FREE DELIVERY. Case MU10 Sickle Bar Mower Operators Manual Plastic Comb – 2017. Cincinnati arrow 500 program manuals. Operators, or owners manuals provide instruction on how to operate your equipment in.

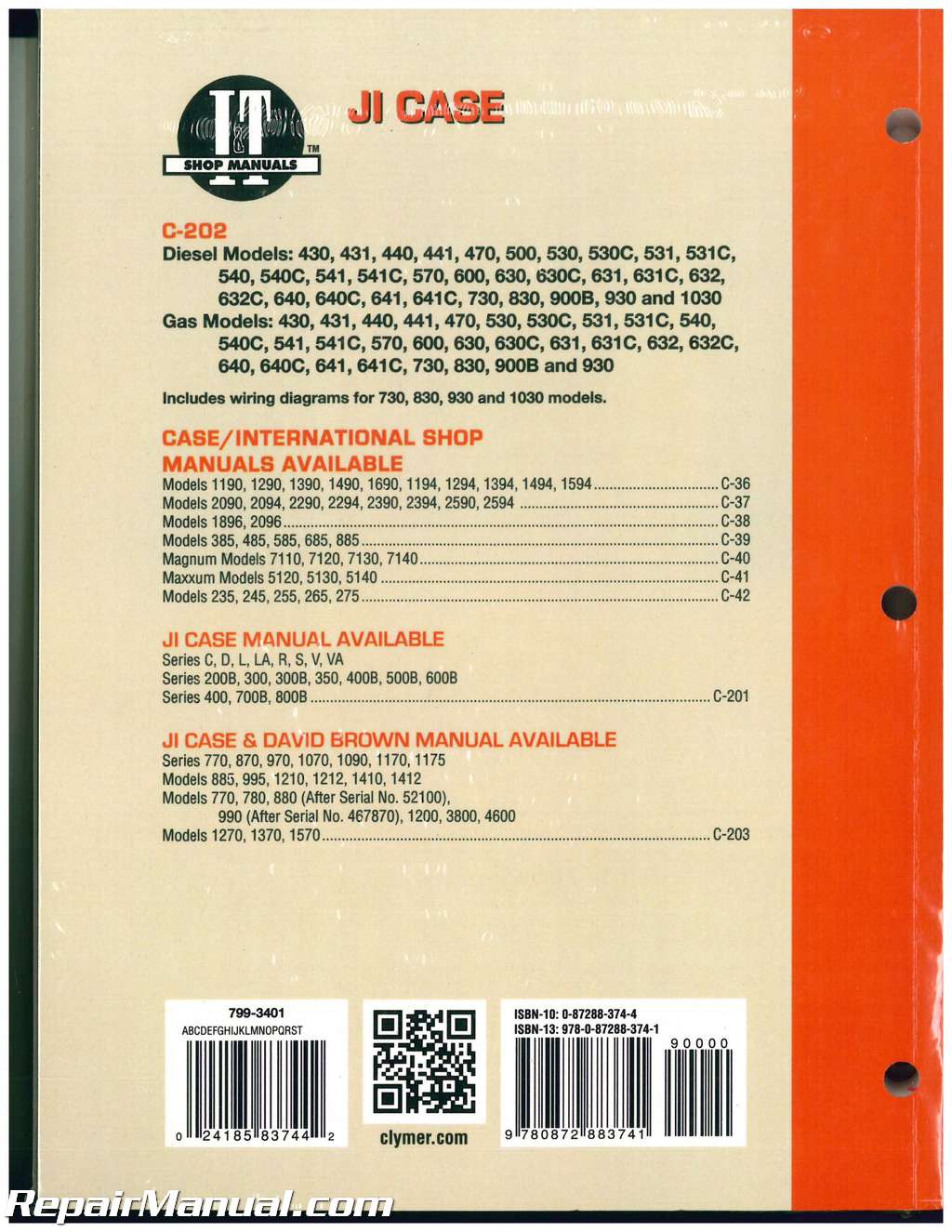

Choose a sub category: Case Manuals We carry the highest quality manuals for Case equipment. Whether it’s routine maintenance or more extensive repairs, our selection of shop manuals provide all the information you need about your Case Machinery. They feature step-by-step procedures so you can operate, repair, service, maintain, and order parts for your Case equipment.

Whether you're a first-time user or an experienced pro, our complete and accurate manuals provide you with all the information you need to get the job done right.

Nice looking machine. Here are a few thouights. Be sure the spring on the breakaway mechanism is set loose enough that the cutter bar assembly swings back if you strike an obstacle. On my John Deere I set it loose enough that I can trip the mechanism by snatching the end of the cutterbar. I figure I don't have the strength to break it, so if it releases at my pull it is safe. Looks like someone substituted pipe for the pittman arm. I think the pittman arm in some mowers is sort of a safety relief that will break if the knife gets jammed.

Unless I knew that the mower is designed for an unbreakable pittman arm I would replace it with a wooden bar. In addition the wood absorbs some of the vibration. The sections (the triangular 'teeth') appear to be in various stages of wear. Those nearest the knife head (the tractor end) seem to be in fairly good shape. You can see that they still have most of the serrations. But those farther out the cutterbar look very worn; if they ever had serrations they no longer do.

Case Model 10 Sickle Mower

I think serrated sections are much better than smooth ones for cutting most everything. Sections are only a couple of dollars each (you need four per foot), so they can be replaced at reasonable cost.

I would use bolts instead of rivets when replacing them because it is easier (to me). The hold downs (the five or six adjustable pieces bolted to the top of the cutterbar) are used to keep the sections pressed against the cutting edges (ledgers) of the guards (the pointy things sticking off the front of the cutterbar). They should put enough pressure on the sections to keep the bottom edge of each section against the ledgers of the guards, but not so much pressure that they wear the guards. The way to test this is to run it for a few minutes and then see if any of the hold downs are too hot to touch; that is a sign that the holddown is too tight. Many years ago, when our father was not around, my brother and I would pee on the hold downs; if they didn't steam we figured all was okay. As sickle mowers are used, the knife back (the 1/4 x 3/4 inch steel bar that holds the sections) tends to warp.

A rock may lodge between a section and guard; even though nothing breaks the knife back may be slightly twisted or bent. Over the years the knife back can become fairly squiggley. At some point the sections don't fit against the guard ledgers very well, and instead of being cut the grass just gets mangled; the grass finally parts, but only because the cutterbar is moving forward and drags it over the sections. Guards are $10-12 each and you need two per foot of cutterbar. Finally, under each hold down should be a thin piece of metal with a bent down edge toward the front; these wear plates keep the knife back from touching and wearing the cutter bar. Be sure your wear plates are not so worn that the cutterbar is being worn.

They a only a couple of dollars each. I have two sickle mowers and enjoy mowing with them much more than my rotary mowers.

But I got both of them (well) used and they began to perform properly only after I replaced the knives (the sections and knifeback), guards, hold downs (get the ones that adjust with a hex screw), and wear plates. That may be $200 or so, even if you shop the aftermarket places, but it sure makes it nice.